About Us

Tactile Materials™

From our founding in 1997 we have developed materials with visual and physical tactility. Touch is thought to be the first sense that humans develop and tactile perception evolves as we discover and experience our surroundings. We understand that tactility is a principal of great architecture. Architects and designers inspire us every day to develop, engineer, and manufacture Tactile Materials™.

Tactile Showrooms™

From the moment you arrive at one of our Tactile Showrooms™ you will be inspired by our materials and products. You will witness the results of rigorous engineering, research and development in all of our Tactile Materials®. Our materials categorized in four distinct typologies, metal, glass, composites and earthen. Our samples are generous in size to better help designers envision the materials and share with their clients. In addition to a plethora of samples and mock-ups, our Tactile Showrooms™ display large format images of projects featuring our Tactile Materials™ and Tactile Products from around the world.

Tactile Lab™

Welcome to Tactile Lab™ where we develop new and adaptive technologies to create exciting materials and products for architecture. Not content with the status quo we drawtechnologies from aerospace, automotive, robotics and biomimicry to create new Tactile Metal, Glass, Composites and Earthen materials. Once we develop the innovative materials we apply them to our Tactile Products™ which are highly engineered solutions for building applications. Some of our products include exterior and interior cladding, sunshades, walking surfaces, public furnishings, large doors and special elements.

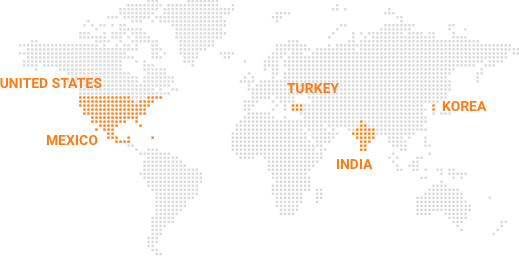

Manufacturing Facilities

With fabrication and assembly facilities in Europe, Asia and North America we operate “Plant within a plant” flexibility to better serve our clients. This revolutionary method allows our plants adapt capacity for each material or product depending on quantities, technical nuances, schedule and logistics.

Our facilities all maintain the same standards for raw materials, production, quality control, packaging regardless of point of origin. Each component or assembly is checked during each stage of production and the final material or product is documented and information is sent with the material or product to the client for reference.

Product Design & Engineering

products for inspired architecture™

Our global and regional product design & engineering centers review each project for the material or product application. We often have architects or building owners requesting a bespoke application of our materials or products. We conduct an engineering assessment during the design of the project to insure that the application is viable.

Once the project enters our operations process the assigned product design & engineering center develops submittal drawings and supporting documents. After approval by the architect the same team develops detailed fabrication and assembly drawings to maintain continuity.