Materials for Inspired Architecture™

Our firm is engaged in the design, engineering, and production of unique architectural products and materials which oftentimes stretch known design assumptions and create a depth of material and form.

Inspired Architecture™

Our inspired architecture™ newsletter highlights projects where the architect embraced our materials or products and then asked “but what if…”

For our firm, it is the highest form of flattery to have architects engage in the process of creating new applications and stretching the boundaries with our materials or products. Although we commit resources and energy to material and product development via our Tactile Labs™, oftentimes the best ideas evolve from an architectural vision. We celebrate those collaborations via the inspired architecture™ newsletter.

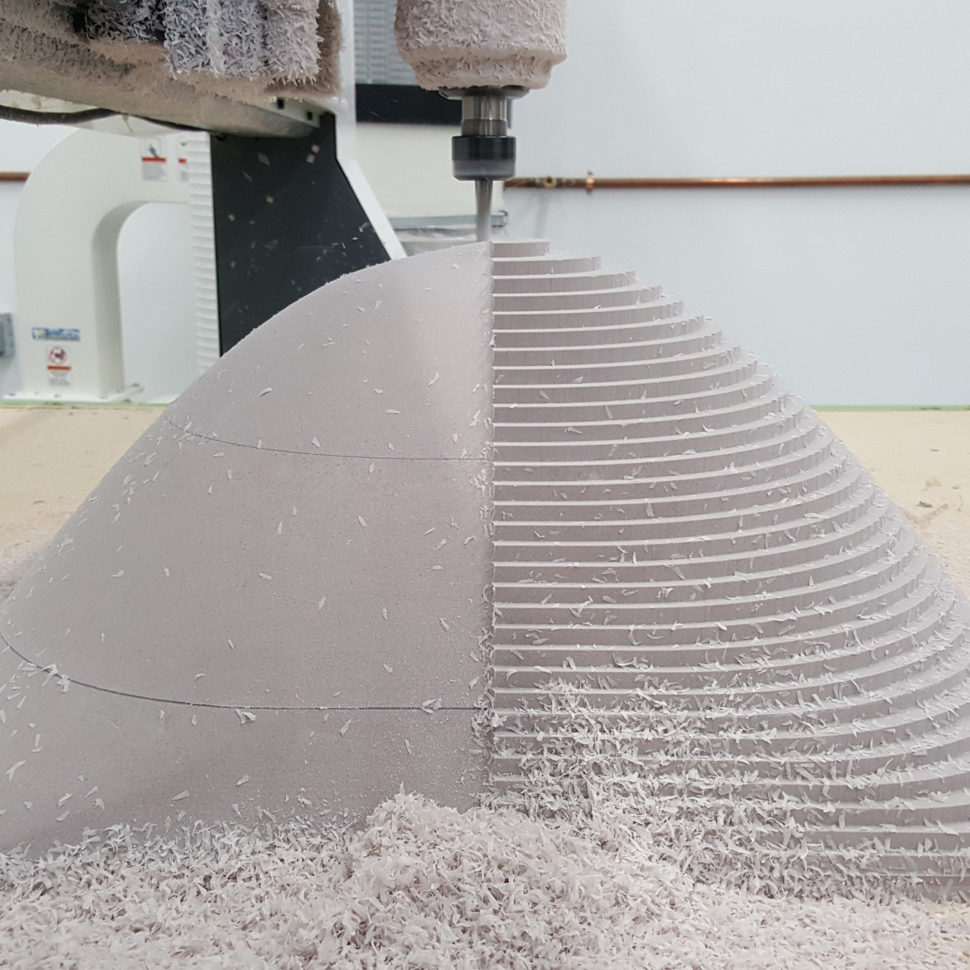

Tactile Spalted Wood Cladding™

Spalted wood patterns created by nature.

Our Tactile Spalted Wood Cladding™ material accentuates maple wood grain with unique and elegant striations created via chemical interactions among fungi in the forests of Vermont. These remarkable patterns can provide a much more distinctive look when used in place of plain wood grain surfaces. Our line of Tactile Spalted Wood Cladding™ products are suitable for interior cladding applications and are available in a number of different stains and finishes.

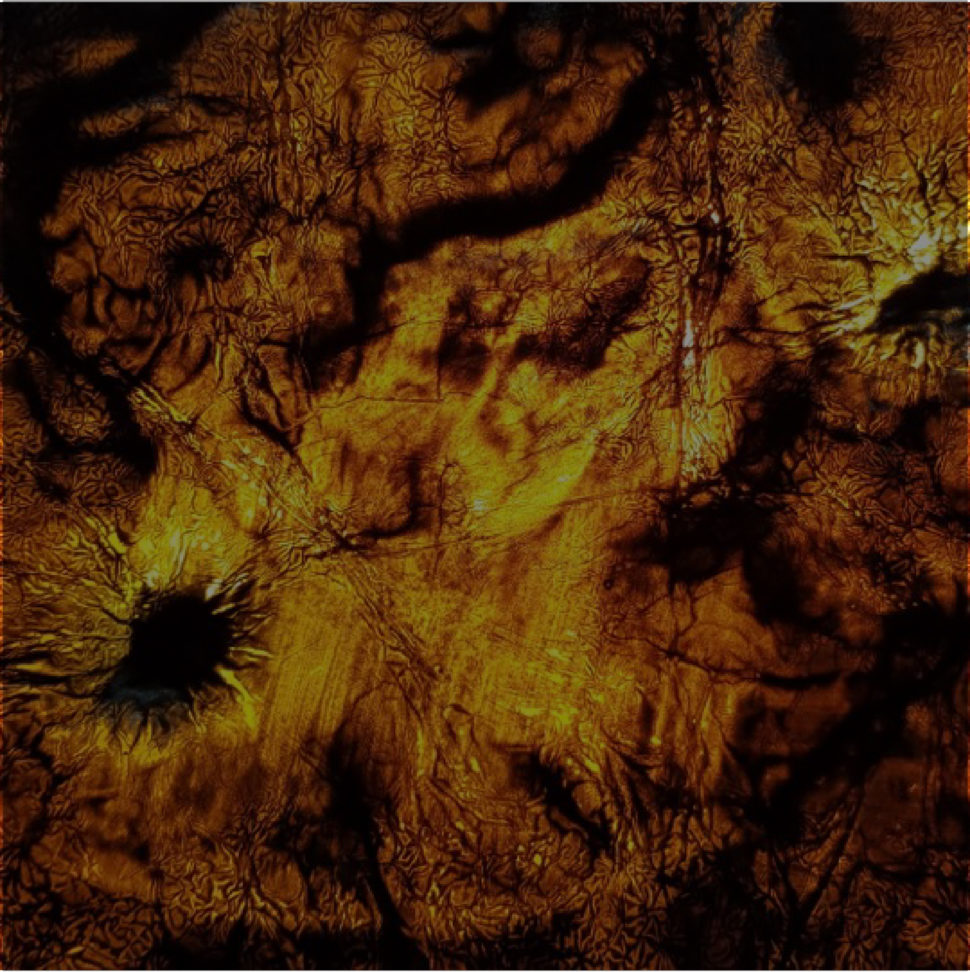

Tactile Cast Bronze Cladding™

A visually organic material our cast bronze conveys warmth and richness unmatched by other metals.

We cast our bronze cladding in various alloys to achieve different tonality and character. We have standard finishes that we have developed over time as well as offering custom project-driven finishes and patterns. We have developed casting methods for solid cladding panels as well as sunshades. Our patinas and coatings allow the architect to determine how the material evolves based on exposure to the environment.

We cast metals using traditional sand, platen, and lost wax investment casting. Each method has distinct advantages and the results offer different levels of refinement and interest.

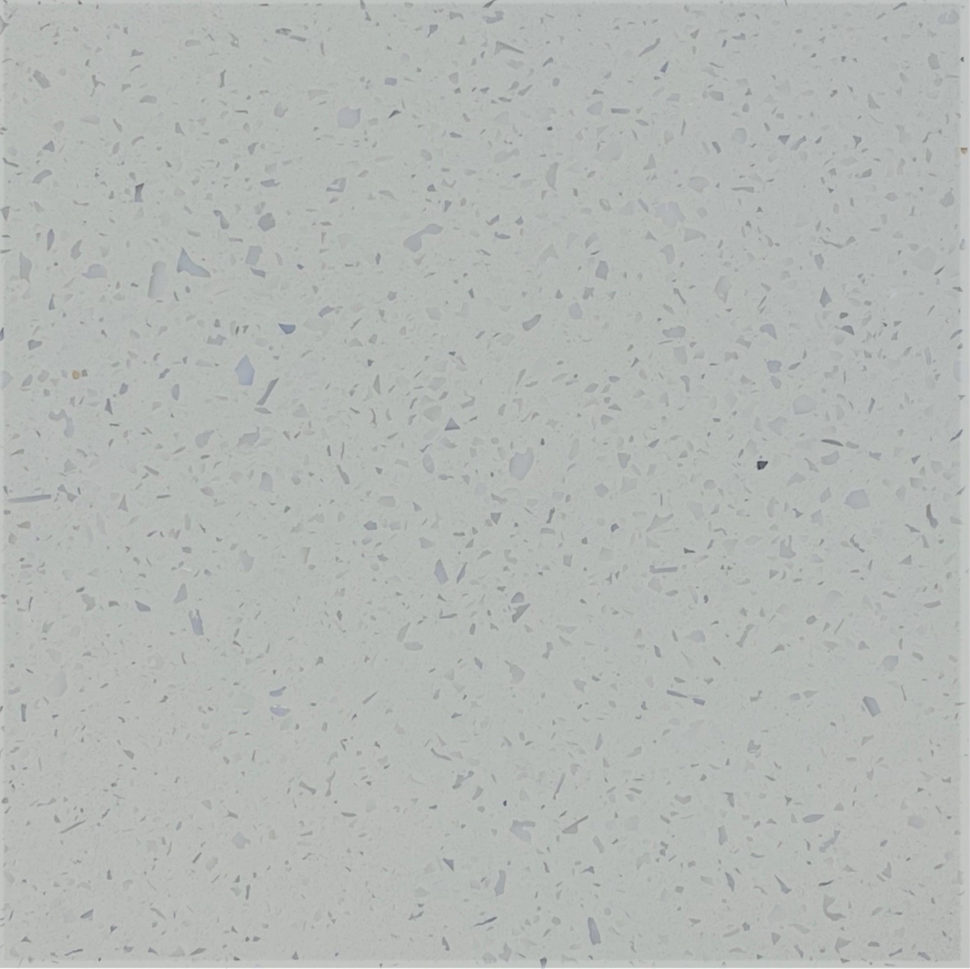

Tactile Cork Cladding™

Natural cork cladding will enhance any environment with warmth and texture.

Cork is a stunning material that takes on a unique aesthetic appearance from highly textured and irregular to monolithic and smooth. We have captured the character of natural material and incorporated cork into our interior and exterior cladding systems. Our interior cork cladding systems allow the material to act as an active solution for acoustical control while providing a beautiful surface.

Our exterior Tactile Cork Cladding™ offers a more organic appearance set within our high-performance rain screen cladding system. Our Tactile Cork Cladding™ system is available with contrasting or illuminated joints to suit your project.

Tactile Porcelain Cladding™ Digital Ceramic

Our Digital Ceramic technology allows Architects and Designers to incorporate high definition images onto our Tactile Porcelain Enamel Metal™ Panels.

Architectural Materials has developed technologies that give Architects and Designers the freedom to take any high definition image and integrate it onto our Tactile Porcelain Enamel Metal™ panels. Now highly detailed artwork can be displayed in a public space while providing the durability that Tactile Porcelain™ offers. Discuss with our design team how our Digital Ceramic technology may provide a solution for your next project.

Tactile Translucent Bronze™

Our Tactile Bronze™ technology has been widely embraced by architects and designers for articulated contemporary facades, historic bronze replacement, and sculptural applications. Our NEW Tactile Translucent Bronze™ in combination with our Tactile Composites™ allows our Tactile Bronze™ to be transformed from opaque to translucent surfaces.

We invite architects and designers to challenge us with patterns, surface textures, and shapes for this new technology. The opportunity to create a truly magical architectural element is within reach!

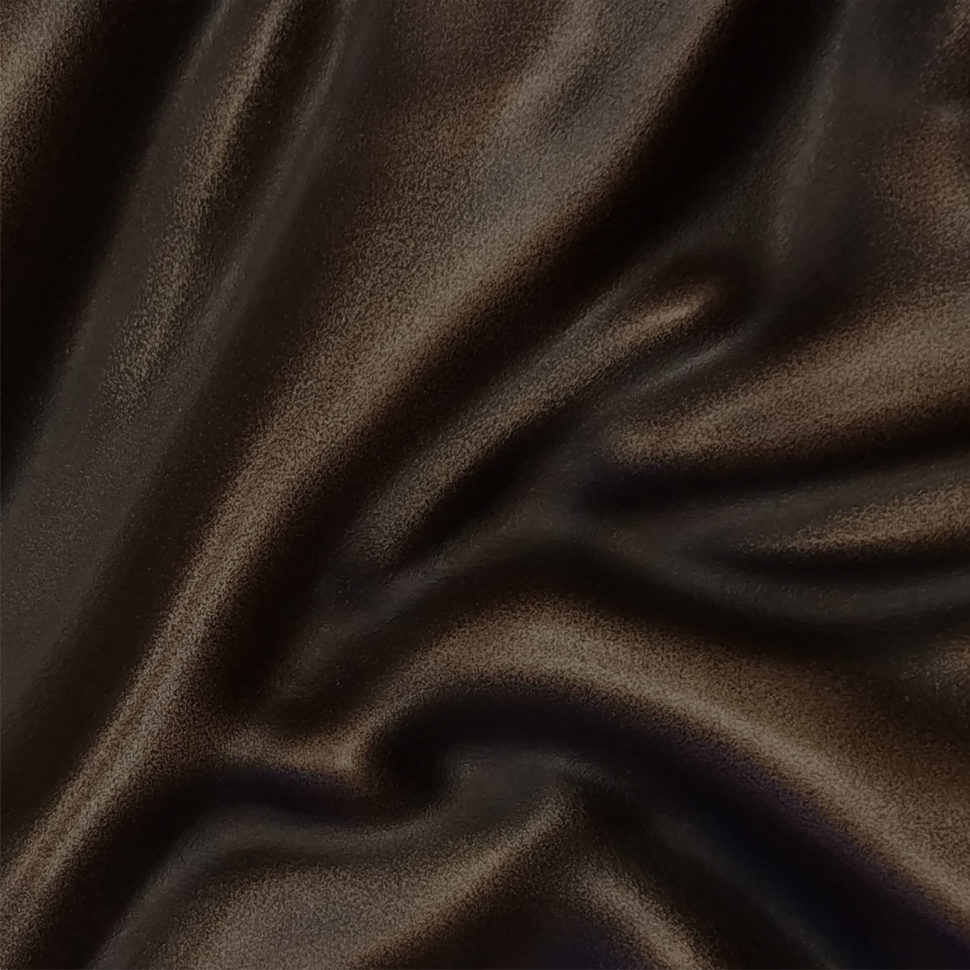

Fully Integrated Tactile Cladding™

Our Tactile Cladding™ spans across our four material categories. This ensures your entire project cladding requirements can be executed by Architectural Materials from design, engineering, manufacturing, assembly, and Install-Assist™. On a recent interior cladding project, we design, engineered, manufactured, assembled, and provided Install-Assist™ for steel sub-framing, Tactile Cast Bronze Cladding™, Tactile Polished GFRC™, and our Tactile Leather Cladding™. Everything fit perfectly….no clashes and tight tolerances of 1/16″ (1.5 mm).

Tactile Melded Metal™

Reflect Metallescent Characteristics For A Fraction Of The Cost.

Architectural Materials has developed Tactile Melded Metal Bronze™ that can be applied to our Tactile Cast Aluminum™ or our Tactile Fiber Reinforced Polymer (FRP)™ materials. Our Tactile Melded Metal Bronze™ finish allows you to achieve the same character and aesthetic quality of solid metal castings at a fraction of the cost. It can also be applied to our Tactile FRP™ substrates to give you a strong, light, and economical solution.

Our Tactile Melded Metal Bronze™ is part of our Tactile Melded Metal™ finishes and is comprised of actual metal. Tactile Melded Metal™ finishes are available in bronze, copper, zinc, chrome and stainless steel suspended in a high-performance polymer. Inquire with our design team about integrating our Tactile Melded Metal™ finishes into your next project.

Global Reach

Global Reach with Local Resources in North America, Europe, and Asia.

We have been privileged to provide our Tactile Materials™ and Tactile Products™ on projects in countries throughout North America, Europe, and Asia. We typically collaborate with architects early in the design process to support the architect’s concepts including charrettes where we discuss the material possibilities and applications. As the projects evolve, we produce project-specific samples and evaluate preliminary engineering requirements. Once the design is determined by the architect, we provide high-level details and specifications to support the project.